To thrive in today’s hyper-competitive market, engineering companies need to transform their own work processes to the speed and data requirements of their telecom customers. They need to guide the evolution of their work processes since they cannot uproot everything at once. There will remain a need for human subject-matter-expertise, even as companies strive to reduce costs and increase flexibility. Because of this, a question frequently being asked is how engineering companies can begin to achieve better business results while moving toward automation and getting high-value expertise from their team members?

Our answer: the Human-in-the-Loop process, known in short as HitL. This theory emphasizes both the importance and benefit of adding automation to the engineering workflow, and the necessity for human expertise to remain an integral part as well. As machine-enabled computing continues to embed itself deeper and deeper into the telecom industry, and frankly, into society as a whole, it is crucial that humans remain involved in the process. Below we will walk through the HitL process to further expand on the idea that an automated network does not infer autonomy.

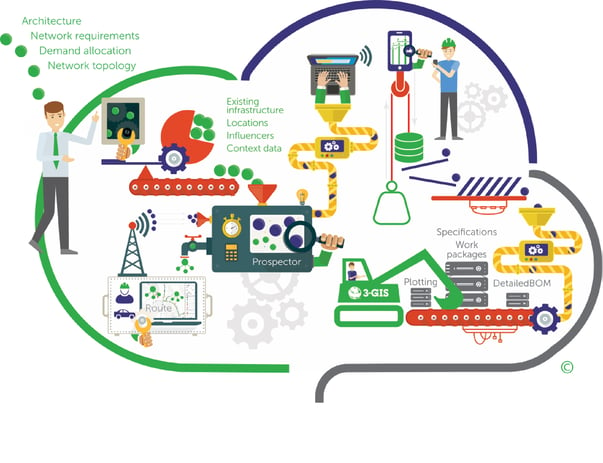

The Human-in-the-Loop Workflow

- Data is gathered for the demand points the network will serve. This typically includes addresses and street data.

- A network engineer will set the network rules. This step allows the engineer to specify how they want the route to be designed in the system, looking at specific network variables such as: existing infrastructure, regulations, geographic barriers, proximity to potential customers, and construction costs to determine the best route.

- Route data is entered into Prospector, 3-GIS’s automated network planning and design tool.

- Prospector generates a least-cost route to the destination points that meets the guidelines set by the network engineer.

- The routes are verified by a network engineer who makes any necessary edits. This could mean changing a buried fiber to an aerial fiber, adjusting the side of the road the route runs down, and more to ensure the route is run and designed according to the engineer’s specifications.

- Prospector uses the updated data to generate a network design with telecom features. This includes placement of splices, structures, slackloops, fiber allocation, and more.

- Field crews perform a construction ride out to verify the constructibility of the routes. These teams can utilize 3-GIS | Mobile to make any required edits directly from the field.

- The engineering team approves the designs and construction and permitting documents are ready to print.

It is evident based on the steps outlined above that including a human in the workflow is critical to ensuring the routes and designs developed through automation are accurate and constructible. Even the most expert systems cannot predict a completely accurate real-world setting for the simple reason of having never experienced the real-world. As opposed to viewing automation techniques as a replacement for human tasks, the two should be viewed more as partners. The machine augmenting the human expertise; the human improving the machine’s computing.

Want to find out more? Take a look at this webinar to hear what some of our experts have to say about HitL and adding automation to their engineering workflow. Skip ahead to 33:48 and 41:29 to find the most relevant content.